Free Resources

Request additional free resources relating to our Post-Process & Finishing solutions:

Let’s Get Started!

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

3075 84th Lane NE, Blaine, Minnesota 55449

How can we help?

At General Pattern Company, we understand that bringing a product to market involves more than just the initial design and manufacturing stages. That’s why our Post Process & Finishing services are an integral part of our comprehensive approach to serving the plastics industry. Our vertical integration of in-house services and finishing sets us apart from our competition by not having to rely on third party vendors for post molding services, saving our customers time and money in delivering the finish solution.

Our commitment is to take our customers through the entire journey, from concept to a finished, and delivered product. We invite you to learn more about our abundance of assembly and finishing services.

What we offer:

At General Pattern Company, we take pride in being your single-source solution for all your manufacturing needs including post-processing and finishing. Utilizing a 1-stop manufacturing process like ours provides immense value and benefits including:

- Holistic Project Management

- Cost-Effective Solutions

- Streamlined Efficiency

- Consistent Quality Control

- Seamless Communication & Collaboration

Our Solutions & Benefits

In-house Class A painting (5 booths), Pad printing, Silk screening, Hot stamping, Laser coding, QR coding, CNC engraving, Decal transfer, Soft touch coating, Brand decorating, EMI/RFI shielding

- Customization: Tailor the color and finish to match your brand identity.

- Durability: Protective coatings for long-lasting, resilient surfaces.

- Aesthetics: Enhance the overall visual appeal of your product.

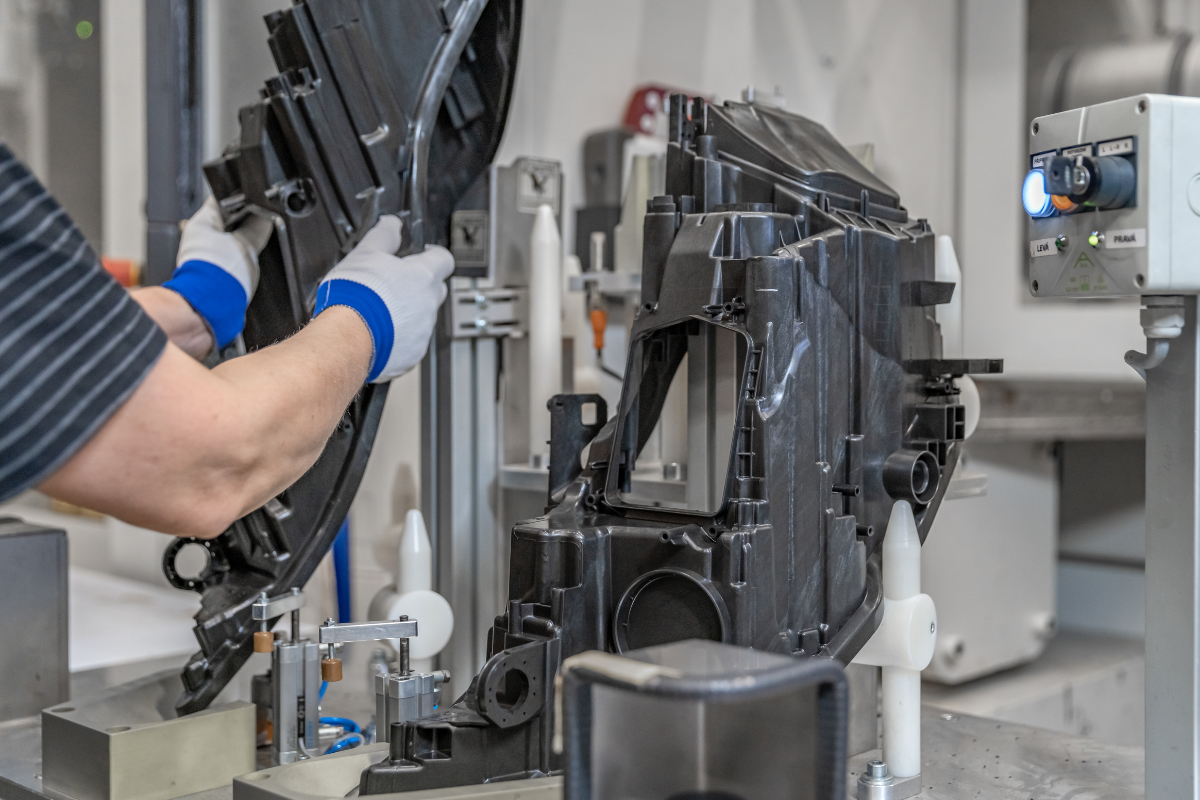

5 welding operations: Hot Plate, Ultrasonic, Spin, Vibration & InfraRed; Heat staking, Solvent bonding, Wire crimping, CNC Lathe, Drilling, Pattern molds, In-house mold texturing, In-house machining of compression limiters,

- Precision: Fine-tune product dimensions and features with utmost accuracy.

- Versatility: Modify and adapt designs for evolving requirements.

- Quality Control: Rigorous inspections to guarantee product excellence.

Our assembly services seamlessly integrate various components into a cohesive, fully functional product. Whether it's a complex assembly or a straightforward integration, our team ensures that every piece comes together flawlessly. The key benefits of our assembly solutions are:

- Efficiency: Streamlined assembly processes for quicker time-to-market.

- Quality Assurance: Stringent checks to guarantee product functionality.

- Scalability: Easily adapt assembly processes to meet varying production needs.

TBD

FAQs

General Pattern Company offers a one-stop solution, integrating design, manufacturing, and post-process services. This streamlined approach ensures efficiency, cost-effectiveness, and consistent quality throughout the entire product development process.

Our 2nd Ops service focuses on fine-tuning and optimizing your product. It includes precision machining, additional assembly, and modifications to meet the highest standards of quality, precision, and functionality.

We maintain rigorous quality control at every stage of the post-process and finishing journey. Our dedicated team ensures that each product adheres to the highest standards, guaranteeing consistent quality and reliability.

We prioritize the confidentiality and security of your intellectual property. Our facility is equipped with state-of-the-art security measures, and our team adheres to strict confidentiality protocols to safeguard your designs and sensitive information throughout the post-process and finishing services.

Absolutely. Our versatile manufacturing capabilities allow us to cater to a wide range of production needs, from small-scale, intricate projects to large-volume manufacturing. We can scale our services to meet your specific requirements and timelines.