Free Resources

Request additional free resources relating to our Rapid Manufacturing services:

Let’s Get Started!

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

3075 84th Lane NE, Blaine, Minnesota 55449

How can we help?

At General Pattern Company, we pride ourselves on being your comprehensive partner in the plastics industry. Our broad spectrum of Manufacturing Services offers a seamless journey from conceptualization to the final product, ensuring efficiency and precision at every step.

General Pattern is one of the few that aligns the volume and size of parts with one of our three divisions. Our unique strategy offers three divisions for low volume, medium/high volume or large parts. Our manufacturing services and experienced team presents options to match product lifecycle, volume and complexity to various processes to gain the best return on your investment in the shortest amount of time.

What we offer:

With over 100 years of experience, General Pattern is recognized as a global leader in custom plastic forming for low volume, large components. Our manufacturing services are designed to accelerate your low to medium volume programs to provide our customers with a competitive advantage.

Our Solutions & Benefits

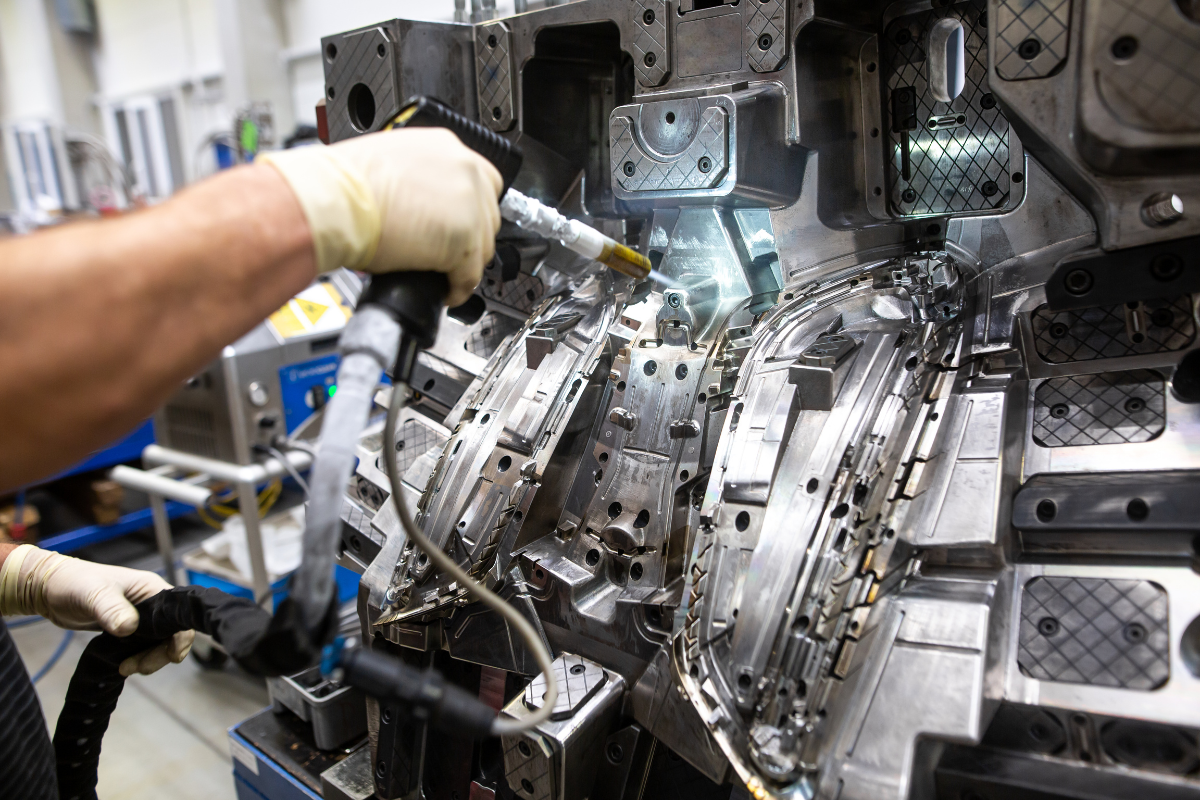

General Patterns’ success comes from our approach and commitment to each customer to provide unparalleled competitive advantage from time to market, quality as well as competitive total costs. The core competency of GPC has expanded to over 85 presses ranging from 65T to over 2000T to insure we continuously have capacity to meet our customer’s growth.

We are the go-to-company for complexity, high engineering value that requires a multitude of services. Having strong relationships with our core resin distributors and decades of experience in plastic injection molding with a wide range of engineered materials has provided us with the expertise to give you the confidence of reliable, consistent delivery. With experience in multiple tool changeovers, GPC has the flexibility to meet your fast-moving targets and deadlines.

Our capabilities include:

- Plastic injection molding

- Large part molding

- Over molding

- Insert molding

- Molded-in color

- Structural foam molding

- Compression molding

- Automation and Gas assist molding

- Metal to Plastic conversion

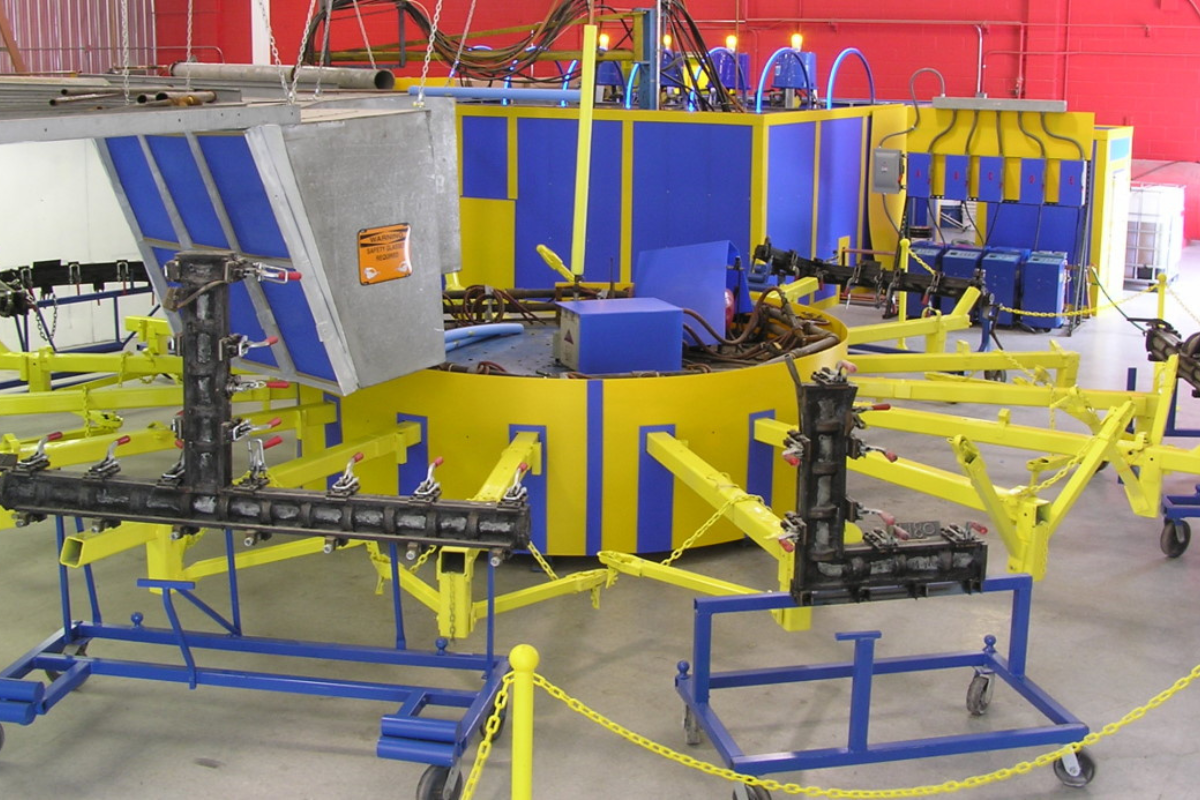

General Pattern’s team are subject matter experts that have the know-how to deliver the small details of large parts. We offer one of the largest fleets of high tonnage presses in the Midwest dedicated to low/medium volume production. With over 40 large ton plastic injection molding presses ranging over 500 tons, General Pattern is equipped to manage your unique program.

In addition to the injection molding processes, General Pattern offers:

- Vacuum forming

- Urethane casting

- RIM molding

- Fiberglass fabrication

- CNC machining

- Warehouse inventory program

General Pattern offers over 20 different processes for a broad offering of services to specialize in and provide options to meet the development needs of our customers projects.

- Urethane Casting

- RIM molding

- Vacuum forming

- I-skin Foam molding

- Fiberglass fabrication

- Roto molding

- Model making

Our versatility allows for the creation of different materials and geometries, ensuring that your product design is faithfully translated into the final manufactured piece.

Quality is about trust. We are committed to never compromising on the quality of our production and prototype services. General Pattern fosters a quality culture that invests in and delivers services that are trusted and preferred by our customers. We are continuously challenging ourselves to improve our quality management systems and equipment.

- ISO 9001:2015

- ISO 14001

- UL certified

- IAFT 16949 (2025)

Our expanded metrology lab offers measurement equipment and services including:

- FARO arm systems

- Fully programmable CMM

- Custom fixtures at the press

- Customized PPAP

- Capability studies

- Reverse engineering for existing parts

For many industries, the transition from metal to plastic components has brought multiple benefits. One of the biggest is lower manufacturing costs. General Pattern offers years of experience partnering with our customers to improve their products, reduce costs and streamline the manufacturing processes by converting components and assemblies to plastic. Advantages plastic offers over metal parts are lighter weights, lower costs, more design flexibility, and often better high impact strength, reduce noise and improved wear surface with lower friction. General Pattern’s approach can consolidate parts and reduce scrap.

FAQs

At General Pattern Company, we understand the importance of time-to-market. The turnaround time for our Rapid Manufacturing services varies based on the complexity and scale of your project. We strive to provide efficient and timely solutions to meet your specific needs. Contact our team to discuss your project timeline and receive a tailored estimate for your manufacturing requirements.

Quality assurance is at the forefront of our Rapid Manufacturing services. We employ rigorous testing and inspection protocols at every stage of the process to ensure that your products meet the highest industry standards. Our commitment to precision and excellence, coupled with advanced manufacturing technologies, guarantees reliable and consistent quality in every product we deliver.

Absolutely. Our Rapid Manufacturing services are designed to be scalable, catering to both small-scale prototyping needs and large-scale production runs. Whether you need a few precision prototypes or high-volume manufacturing, we have the expertise and capacity to accommodate a wide range of project sizes. Contact us to discuss the specifics of your manufacturing requirements.

- General Pattern Company offers a diverse range of materials suitable for Rapid Manufacturing services, including plastic injection molding and foam molding. We work with various plastics and foam materials, each selected for its unique properties. Our team can guide you in choosing the material that best suits your project's requirements in terms of strength, flexibility, and other considerations.

Collaboration is a fundamental aspect of our Rapid Manufacturing process. We believe in a transparent and communicative approach, working closely with our clients to understand their vision, address challenges, and ensure that the final product aligns with their expectations. Throughout the manufacturing journey, our team maintains open lines of communication, providing regular updates and seeking client feedback to ensure a successful and collaborative manufacturing experience.