General Pattern Company, Blaine, Minnesota, is excited to announce the investment of the Mantle P-200 metal 3D printer, making them one of the first to implement this innovative technology as part of their in-house toolmaking division for prototyping and production.

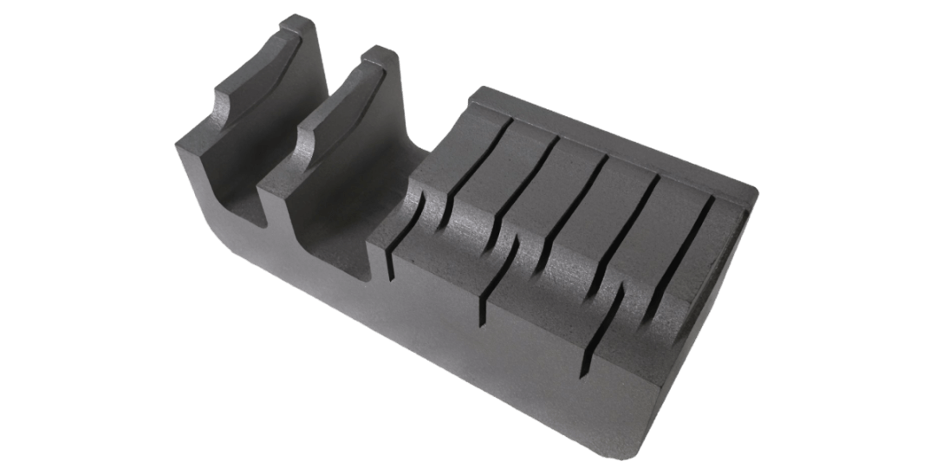

Mantle’s P-200 printer is the only 3D printer that is designed specifically for tooling. Built on a trusted CNC platform, the P-200 integrates the printing of Mantle’s metal pastes with CNC machining to produce precision H-13 tool steel components in less time and with accuracy.

The decision to adopt the Mantle 3D technology stems from General Pattern’s commitment to staying at the forefront of technology. Using the Mantle metal 3D printer, GPC has the flexibility to build production tools at prototype lead-times and minimize the need to build entire tools by the toolmakers which significantly reduces costs, lead times and labor. With its exceptional tolerances, the P-200 also minimizes post-work required on tooling enabling GPC to deliver samples quickly, expediting the entire submission process. General Pattern anticipates the benefits of this investment to include new market entry, decreased reliance of specialized labor and improved customer service through faster and more efficient operations.

“At GPC, we pride ourselves on taking products from development through to production, which includes in-house prototype and production tooling. Introducing Mantle into our operations has elevated our approach to toolmaking. With the simple press of a button, we can now effortlessly create tools or inserts, which completely changes our ability to tackle labor challenges and enhances our capacity to better serve our customers.” – Denny Reiland, CEO at General Pattern

About General Pattern Company

Founded in 1922, General Pattern is a fourth-generation, woman-owned custom manufacturer specializing in low to medium plastic forming operations. When you align with us, you work with a multi-faceted and responsive partner that operates with a sense of urgency and accountability. The strength of GPC is our broad selection under one relationship. The wide range of value-added operations and in-house tooling, as well as our extensive range of prototype and production processes including 85 injection molding presses gives our customers options.

At General Pattern, we work with an unwavering commitment to quality, seen through our ISO 9001:2015 certified facility and soon to be ISO 16949 certified in 2024. To start a relationship today, visit www.generalpattern.com.