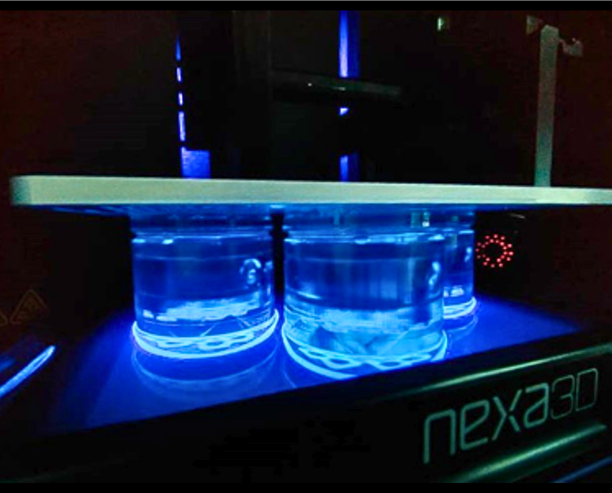

General Pattern Company, Blaine, Minnesota, is thrilled to unveil the investment with Nexa3D Freeform Injection Molding (FIM) that continues to revolutionize the rapid prototyping industry. By merging the design flexibility of 3D printing with the mechanical properties of injection molding, this partnership offers a game-changing solution for engineers and product developers.

The FIM process leverages DLP technology to create fully functional soluble molding tools compatible with a wide range of injection molding materials including PEEK, LSR and Ceramic. This allows the molding of complex parts using final-grade materials within a single day, significantly accelerating the prototyping and validation process.

The decision to be the first in the Midwest to invest in the Nexa3D Freeform technology underscores GPC’s commitment to innovation and providing customers with cutting edge solutions. By utilizing the FIM technology, engineers can drastically reduce both the time and cost in hours to put parts in hands for swift validation, testing and customer acceptance with production materials. The benefits are ideal for early-stage development, product demonstrations, validating material performance and next generation design testing.

Denny Reiland, CEO of General Pattern, highlights the transformative impact of this technology, emphasizing the ability to iterate quickly and bring higher-level decision-making into the early stages of development. With the ability to produce multiple prototype molds at a fraction of the traditional cost and time, GPC’s “Mold in Minutes” technology empowers customers to experiment, innovate, and refine their designs with unparalleled flexibility and efficiency.

About General Pattern Company

General Pattern, founded in 1922, stands as a testament to longevity, resilience, and adaptability in the manufacturing industry. As a fourth-generation, woman-owned company, we take pride in our heritage and our commitment to excellence. One of our core strengths at GPC lies in our comprehensive range of capabilities all under one roof.

From low to medium plastic forming operations to an extensive of value-added services and in-house tooling, we offer a holistic solution to your manufacturing needs. Our wide array of prototype and production processes, including access to 85 injection molding presses, ensures that you have a wealth of options at your disposal.

At General Pattern, we work with an unwavering commitment to quality, seen through our ISO 9001:2015 certified facility and soon to be ISO 16949 certified in 2024. If you’re ready to embark on a mutually beneficial partnership built on trust, reliability, and quality, we invite you to reach out to us today at www.generalpattern.com