Free Resources

Request additional free resources relating to our Rapid Prototyping services.

Let's Get Started!

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

3075 84th Lane NE, Blaine, Minnesota 55449

How can we help?

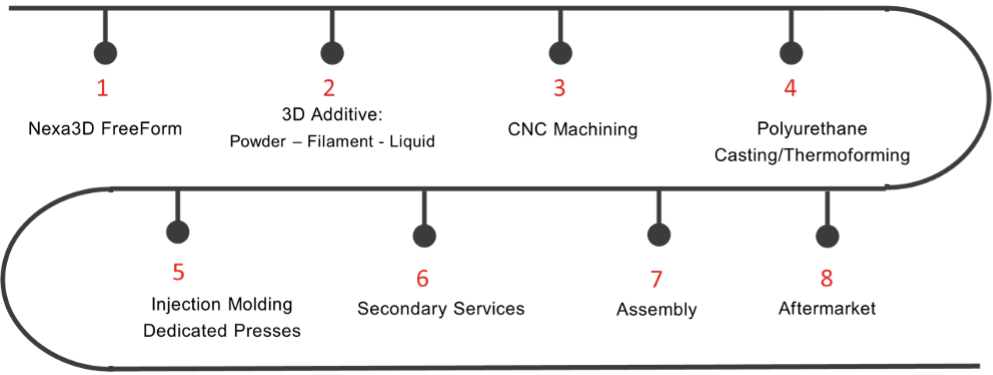

General Pattern Company offers a dedicated division focused on quick turnaround, cost-effective solutions that can facilitate evaluation of a part’s form, fit and function. We offer a full range of technologies from plastic injection molding prototyping, polyurethane casting, roto molding, vacuum-forming to a full range of additive manufacturing, including traditional CNC machining and 3D printing.

Our commitment to innovation and excellence in the plastics industry enables us to be your solution for early development needs, making your idea/concept a reality. We understand the importance of verifying the design and function before investing in tooling, or the requirement of workable parts for tradeshows or regulatory approval. With over 50 years of experience of on-demand solutions, our prototype division along with the flexibility of a full range of secondary operations will get parts in your hands quickly and with no need to compromise on your design.

What we offer:

- Full-service plastics prototype division specializing in over a dozen different processes

Our Solutions & Benefits

Turning great ideas into successful products is our mission for our customers. Prototypes are important in the development process and risk mitigation. We offer a comprehensive range of solutions that will take your idea from concept to parts with speed, so your design team can get to the next steps faster.

Prototype Options

General Pattern offers three material formats Powder, Liquid resin and Filment. We have over 15 machines to deliver various attributes and sizes: MJF, SLA, SLS, DLP, FDM, FFF and Carbon. We also offer SLM for aluminum and 316L steel.

General Pattern's vertical integration applies to our prototype division in servicing short runs for development and pre-production for testing and validating with production-level quality.

IM - PUC - RotoMold - Fiberglass - Thermo/Vacuum forming

Our state-of-the-art CNC machining capabilities provide precision and versatility. We can rapidly create intricate parts and molds with exceptional accuracy. Whether you need a prototype for testing or require custom tooling, CNC machining ensures speed and precision in your development process.

General Pattern's full array of finishing and post processing services are available for prototype needs so our customers do not need to settle for close enough. Services include painting, welding, pad printing and assembly.

General Pattern is an early adaptor to our newest investment of the only 3D printer designed specifically for tooling. Utilizing H13 steel, Mantle shortens leadtimes to get parts in our customers hands faster.

Ideal for early-stage development, Freeform Injection molding provides soluble tooling to print prototypes in 48 hrs utilizing injection molding resin such as Peek, LSR & PUC. Test concepts quickly.

FAQs

Our turnaround time varies based on the complexity of the project and the chosen prototyping method. Generally, we strive for industry-leading speed, ensuring you receive your prototype in the shortest possible time without compromising quality.

CNC machining and 3D printing serve different purposes in the prototyping journey. CNC machining is ideal for producing precise, functional components, while 3D printing excels in creating complex geometries quickly. The combination of both technologies allows for a comprehensive and efficient prototyping process.

The finished dimensions of urethane cast parts depends on the accuracy of the master model, part geometry and casting material. In general, a shrinkage rate of +0.15% is expected.

Absolutely. Our tooling solutions are tailored to meet the unique requirements of each project. Whether you need molds for mass production or specialized tooling for a particular manufacturing process, our team works closely with you to deliver customized solutions that optimize efficiency and maintain high-quality standards.

Our services are designed to streamline the product development and manufacturing processes. By reducing lead times, minimizing design modifications, and optimizing manufacturing efficiency, we help you save both time and resources. The result is a cost-effective journey from prototype to production without compromising on quality.