Single Source Solutions

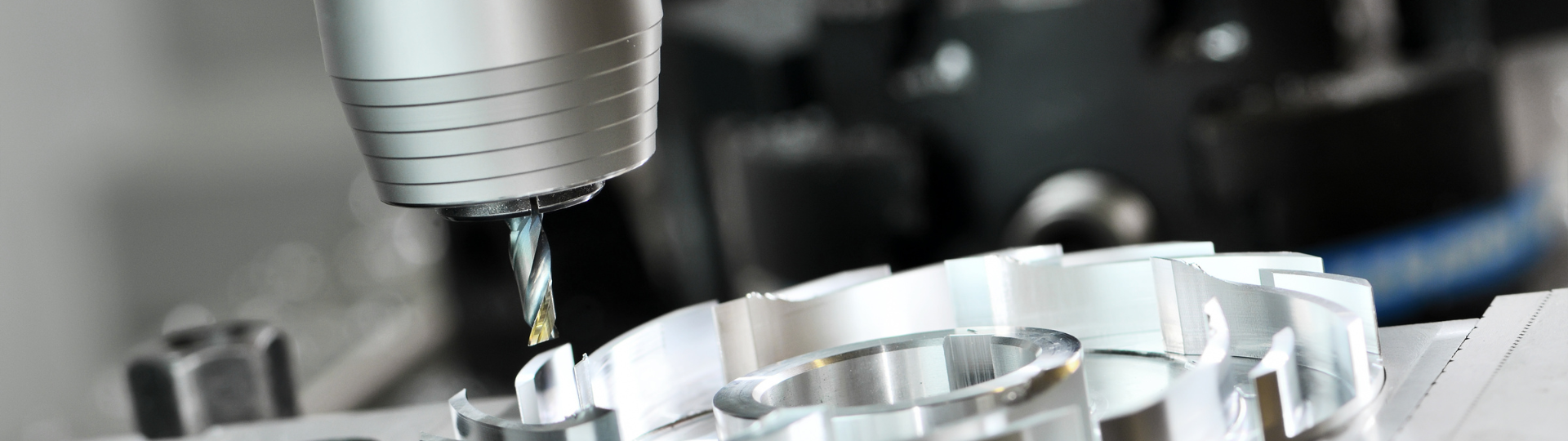

Prototyping

Offering efficient and cost-effective solutions to create tooling, fixtures, and prototypes for various industries.

Engineering/Tooling

Proactive collaboration brings your products to market On-Time and On-Budget.

Manufacturing

Offering a seamless journey from conceptualization to the final product for low to medium volume.

Post Process/Finishing

Offering solutions to bring your products from concept to delivery.

Building Lifelong Relationships

At General Pattern Company, we are more than just a manufacturing company; we are your trusted partner in bringing innovation to life. As a full-service manufacturer dedicated to serving Original Equipment Manufacturers (OEMs), we take pride in offering a comprehensive range of services, including design, engineering, prototyping, tooling, production, assembly, and distribution. Our commitment to being a single source solution means we streamline the manufacturing process, making it easier for our clients to bring their products to market efficiently.

As a vertically integrated company, we control every aspect of the manufacturing process in-house, from raw material sourcing to finished product assembly. This not only ensures quality and precision but also leads to cost savings, providing our clients with a competitive edge in their industries. Our core values of Dependability, Hard Work, Always Finding A Way, and Fun drive us to excel in everything we do. We are dedicated to fostering long-term relationships with both our customers and employees, creating a legacy of profitability and excellence in the manufacturing industry.

Denny Reiland,

CEO of GENERAL PATTERN CO.

Our Projects

Consumer Electronics

Transportation

Aerospace

Medical

Find Out More About Us

Since 1922, General Pattern Company has been involved in a variety of plastic forming technologies priding itself on the ability to take customers from their earliest design concepts and prototyping needs all the way through to production and assembly.

Dependable

As a reliable source to our customer, we pride ourselves on the ability to meet and exceed expectations.

Hardworking

Our team is passionate about their work and eager to embrace new ideas, processes, and technologies.

Always Finds a Way

In an industry where technology and processes are forever changing, we adapt to new and improved ways to do business.

Fun

Work hard, play hard! We value relationships built within a culture and environment our team and customers can enjoy.

OUR MISSION

We are committed to financial excellence, with a minimum target of $225,000 per head and a 95% or higher Right-First-Time (RFT) production rate, demonstrating our dedication to quality and efficiency. We maintain corporate PPMs (Parts Per Million) of 500 or less to ensure exceptional product quality and strive for a corporate On-Time Delivery (OTD) rate of 95% or better, guaranteeing that our clients can rely on us to meet their project timelines.

OUR VISION

To become the leading manufacturer in the nation for low-volume, large plastic parts produced from aluminum tooling. We aspire to set new standards of excellence in this niche market and continuously innovate to meet the evolving needs of our clients. By achieving this vision, we aim to solidify our position as the go-to partner for OEMs seeking high-quality, reliable manufacturing solutions.

1922 - Founded by Ernest Reiland in St. Paul, Minnesota

In 1922, manufacturing pattern shops were pivotal in American industry. Skilled artisans crafted wooden patterns used in foundries to create metal castings, playing a crucial role in producing various industrial components and architectural elements.

1983 - Opened Blaine Facility, Main Headquarters

In 1983, the plastics manufacturing industry was rapidly expanding. Innovations in materials and processes led to the production of diverse plastic products, transforming industries such as automotive, electronics, and consumer goods.

2013 - Woman Owned, Staci Thill

General Pattern Company underwent a transformative shift, becoming a woman-owned business through a partnership between Denny Reiland and his daughter, Staci Thill. This transition marked a commitment to diversity and continued family leadership in the company’s legacy.

2022 - Opened Facility in Wyoming, Minnesota

General Pattern Company’s facility expansion in Wyoming, MN was a significant milestone, dedicated to housing four large tonnage machines ranging from 1500 to 2200 tons. This expansion increased their injection press count to an impressive total of 78.

3,120

Happy Customers

14

Vertical Processes

1,200

Machine Capacity (hrs)

25

Range of Capabilities

Testimonials

...The Engineering Team here at IAC feel you have done an excellent job fulfilling our requirements from a Quality, Cost, and Timing perspective. The components were completed ahead of schedule, assembled very well, and our Customer was extremely satisfied with the quality of the doors as assembled. On behalf of the Engineering Team, Thank you.

Dave Mikulski

Engineering Supervisor, IAC Group

Mark Tobler and his team have done an extraordinary job in supporting this project every step of the way...He has made himself accessible whenever we need him and has consistently provided information to us in a timely manner....We basically went from concept initiation in mid-October to implementation on January 5, something we could not have achieved without General Pattern's assistance.

Rachel Hintz

Development Purchasing Analyst, Harley Davidson

This year, we produced over one million Bobcat® loaders, which is an accomplishment more than 55 years in the making. We know we could not have reached this landmark number without an exceptional network of suppliers, vendors and service providers - true partners...General Pattern provides quality product at a fair cost...continually drive innovative ideas to lower cost...[and] work well with our supplier development group to drive lean improvements in their factories.

Rich Goldsbury

President, Bobcat Company

[General Pattern Co. has] receiv[ed]...certificate in appreciation and recognition for achieving the targeted Supplier Performance criteria in the following areas for the Sanford facility. PPM (Part per million), SSP (Supplier Shipping Performance), ASN (Advanced Shipping Notice), PPAP (Production Part Approval Process), [and] POU (Point of Use)...Again thank you for your dedication in supporting our machine production and for taking pride and diligence in the component parts that you provide.

Charles Keltz

BCP Sanford Site Purchasing Supervisor, Catepillar Inc.

Our Leadership

Staci Thill

Julie Otten

Denny Reiland

Rhonda Hechsel

Dan Thill

Kym Peterson

Single Source

Manufacturing Solutions

Focused on building life-long relationships.